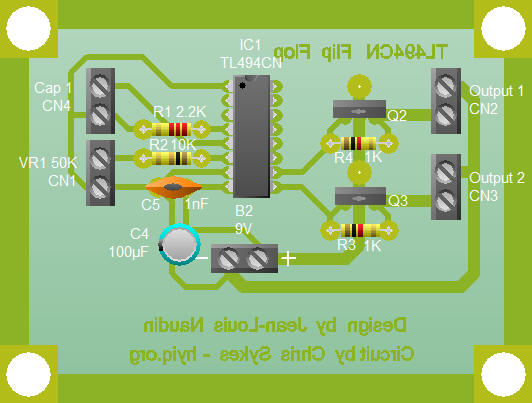

| The MEG Driver Circuit:

Initially I will be using a variant

of the MEG Circuit from Jean-Louis Naudin.

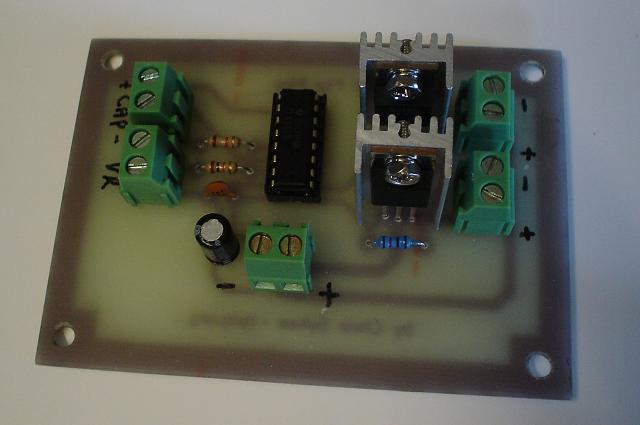

My replication of Jean-Louis Naudin's

Circuit:

Click Here or on the Picture to download the

Circuit Wizard Circuit File.

Download Circuit Wizard 30 Day Trial here.

Click Here

for the TL494CN PWM Chip Datasheet.

Get your TL494CN's from Mouser Electronics.

The J.L. Naudin

circuit, above, is a 50% Duty Cycle, so the circuit has two channels,

one channel is on 50% of the time then off the other 50%, the other

Channel is 180 degrees out of phase, when channel one is on, channel

2 is off and vice versa.

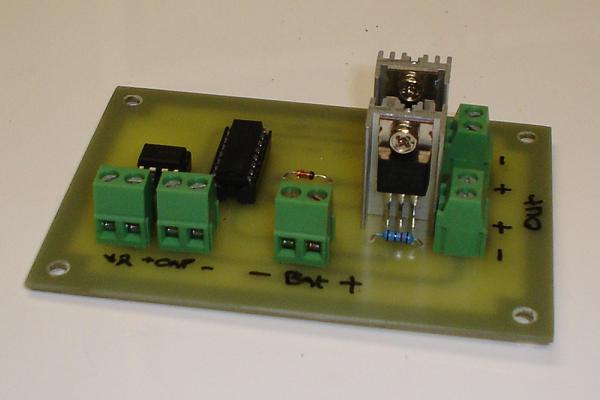

Most likely

I will be using another circuit to Drive the Actuator coils. This

Circuit will be a basic Fett Switching circuit and more information

will be posted soon about this.

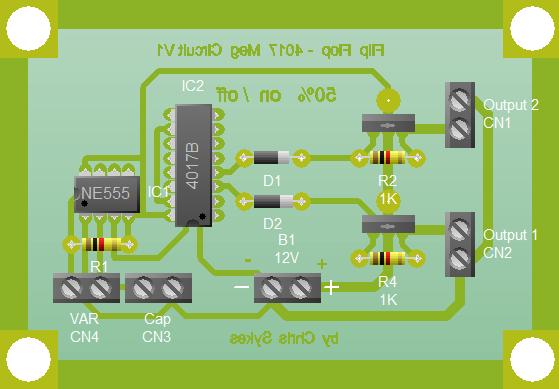

I am also looking

at a 25% duty cycle driver circuit. I am building the circuits modular

for a few reasons. The main reason is that it makes it easier to

change one small part of the circuit if I need to.

Click Here or on the Picture to download the

Circuit Wizard Circuit File.

Above, in a

25% duty cycle circuit, again we have two channels, the Circuit

is off 25% of the cycle, then channel one moves to an on state 25%

of the cycle, then again the circuit goes into an off state 25%

of the cycle, then channel two moves to an on state 25% of the cycle.

Because 4 x 25% = 100% this is one full cycle. We can see here the

circuit is actually off 50% of the full cycle.

Ref for

Duty Cycle:

http://en.wikipedia.org/wiki/Duty_cycle

|